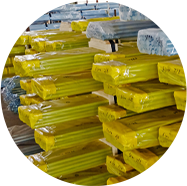

An enterprise specializing in the production of all kinds of cold drawn steel and cold-formed steel

The annual production capacity is more than 10000 tons, and the product quality can meet the national standard

Sutong special cold drawn steel Co., Ltd. is an enterprise specialized in producing all kinds of cold drawn steel and cold formed steel

haveProcess flow technical force

And batch productionOperation expert

Adhering to the enterprise spirit of "unity and enterprising, pragmatic entrepreneurship", we will create a brilliant tomorrow with you

Located in Suzhou Changshu Liantang Town Development Zone where Wuxi, Shanghai and Zhangjiagang meet, it has developed transportation and convenient communication

The company covers an area of 14000 square meters and has complete production facilities. The equipment includes four production lines of 40 ton, 20 ton and 10 ton pullers, one 25 ton resistance annealing furnace, two large shot peening machines and a set of environmental protection treatment facilities and equipment.

The company has process flow, technical force and a number of production and operation experts. We will, as always, pursue the business philosophy of "sincerity, enthusiasm and wholeheartedness" to win customers' confidence, achieve the goal of "win-win" and create our own values.

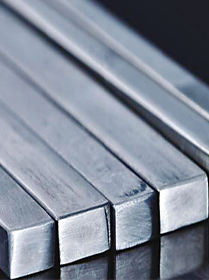

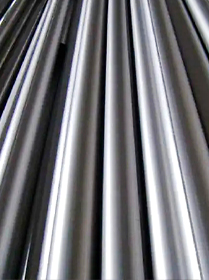

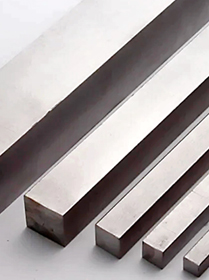

Product specification: s5-s55 cold drawn hexagonal steel, diameter 5-65 cold drawn round steel, 5*5-55*55 cold drawn square steel, 3*12-30*110 cold drawn flat steel, and cold drawn profiled steel and cold formed profiled steel with different specifications.

All employees of the company, adhering to the quality tenet of "quality first, customer first", the enterprise spirit of "unity and enterprising, pragmatic entrepreneurship", and the excellent management, quality and after-sales service, will create a brilliant tomorrow with you.

Lean manufacturing to perfect service to create quality engineering of fluid conveying system

The spinning process usually includes core processes such as opening and carding, drawing, roving, and fine yarn. The spinning machine accessories of different processes play their respective roles, jointly ensuring the quality and production efficiency of the yarn. The specific applications are as follows:

Machining components (parts made through machining processes such as turning, milling, drilling, grinding, boring, stamping, forging, etc.) are the core foundation of modern industrial production, and their application scenarioses cover almost all industrial fields that require precision assembly, mechanical performance support, or functional implementation. The core logic is that as long as the sce

Hexagonal bars (including cold drawn, hot-rolled, stainless steel and other materials, with the core advantages of structural stability, uniform force distribution, easy wrench fastening, and convenient installation and disassembly) are mainly used in three major scenarioses in the construction field: "connection and fixation, structural support, and decorative beautification", especially suitable f

The spinning process usually includes core processes such as opening and carding, drawing, roving, and fine yarn. The spinning machine accessories of different processes play their respective roles, jointly ensuring the quality and production efficiency of the yarn. The specific applications are as follows:

Machining components (parts made through machining processes such as turning, milling, drilling, grinding, boring, stamping, forging, etc.) are the core foundation of modern industrial production, and their application scenarioses cover almost all industrial fields that require precision assembly, mechanical performance support, or functional implementation. The core logic is that as long as the sce

Hexagonal bars (including cold drawn, hot-rolled, stainless steel and other materials, with the core advantages of structural stability, uniform force distribution, easy wrench fastening, and convenient installation and disassembly) are mainly used in three major scenarioses in the construction field: "connection and fixation, structural support, and decorative beautification", especially suitable f

Angle iron is suitable for large-scale processing, mainly because its material characteristics and structural form are suitable for industrial mass production, and the processing technology is mature and efficient. The specific supporting points are as follows:

The core application of the door shaft is to achieve the rotation and opening and closing of the door/cover. It is used in all scenarioses involving openable and closable structures, covering multiple basic industries. The concentrated areas of use are as follows:

The wear resistance of textile machinery accessories varies depending on the material, structure, and application scenarioses, and is closely related to the type of accessory and processing technology. 1. Wear resistance performance of different types of accessories Transmission accessories, such as gears, rollers, and transmission shafts, are often made of alloy steel or carbon steel that

The core function of hexagonal bars is to serve as the basic profile for mechanical manufacturing, hardware accessories, and other fields. With the structural advantage of hexagonal cross-section, they have the functions of structural support, transmission connection, and convenient assembly, and are widely used in the production of various precision parts and structural components.

The core function of a door hinge is to connect the door and the door frame, while achieving flexible opening and closing, stable load-bearing, and positioning of the door. It is a key hardware component that ensures the normal use of the door, and its specific functions are reflected in four core dimensions.

The application of anti-theft door components in warehousing scenarioses revolves around "secure storage, efficient management, protection against wear and tear, and adaptation to production/circulation needs". It is necessary to design targeted warehousing solutions based on the characteristics of different types of components (such as structural components, hardware components, electronic componen

Petroleum exploration components are the core equipment components used in the process of petroleum exploration (from surface detection to underground formation analysis) to "obtain geological information, identify oil and gas reservoirs, and ensure the safety of exploration operations", covering the three core links of "surface exploration, drilling exploration, and logging exploration". The func

The spinning process usually includes core processes such as opening and carding, drawing, roving, and fine yarn. The spinning machine accessories of different processes play their respective roles, jointly ensuring the quality and production efficiency of the yarn. The specific applications are as follows:

Machining components (parts made through machining processes such as turning, milling, drilling, grinding, boring, stamping, forging, etc.) are the core foundation of modern industrial production, and their application scenarioses cover almost all industrial fields that require precision assembly, mechanical performance support, or functional implementation. The core logic is that as long as the sce

Hexagonal bars (including cold drawn, hot-rolled, stainless steel and other materials, with the core advantages of structural stability, uniform force distribution, easy wrench fastening, and convenient installation and disassembly) are mainly used in three major scenarioses in the construction field: "connection and fixation, structural support, and decorative beautification", especially suitable f

Angle iron is suitable for large-scale processing, mainly because its material characteristics and structural form are suitable for industrial mass production, and the processing technology is mature and efficient. The specific supporting points are as follows:

The core application of the door shaft is to achieve the rotation and opening and closing of the door/cover. It is used in all scenarioses involving openable and closable structures, covering multiple basic industries. The concentrated areas of use are as follows:

The wear resistance of textile machinery accessories varies depending on the material, structure, and application scenarioses, and is closely related to the type of accessory and processing technology. 1. Wear resistance performance of different types of accessories Transmission accessories, such as gears, rollers, and transmission shafts, are often made of alloy steel or carbon steel that

The core function of hexagonal bars is to serve as the basic profile for mechanical manufacturing, hardware accessories, and other fields. With the structural advantage of hexagonal cross-section, they have the functions of structural support, transmission connection, and convenient assembly, and are widely used in the production of various precision parts and structural components.

The core function of a door hinge is to connect the door and the door frame, while achieving flexible opening and closing, stable load-bearing, and positioning of the door. It is a key hardware component that ensures the normal use of the door, and its specific functions are reflected in four core dimensions.

The application of anti-theft door components in warehousing scenarioses revolves around "secure storage, efficient management, protection against wear and tear, and adaptation to production/circulation needs". It is necessary to design targeted warehousing solutions based on the characteristics of different types of components (such as structural components, hardware components, electronic componen

Petroleum exploration components are the core equipment components used in the process of petroleum exploration (from surface detection to underground formation analysis) to "obtain geological information, identify oil and gas reservoirs, and ensure the safety of exploration operations", covering the three core links of "surface exploration, drilling exploration, and logging exploration". The func